亮點(diǎn)評(píng)述

化工學(xué)報(bào)|一種抑制隧道排水管道中結(jié)晶體形成的雙層阻垢疏水涂層

一種抑制隧道排水管道中結(jié)晶體形成的雙層阻垢疏水涂層

胡家瑋  王聰劉美婧

王聰劉美婧

(蘭州理工大學(xué)土木工程學(xué)院,甘肅 蘭州 730050)

DOI:10.11949/0438-1157.20241325

引 言

1 依托工程概況

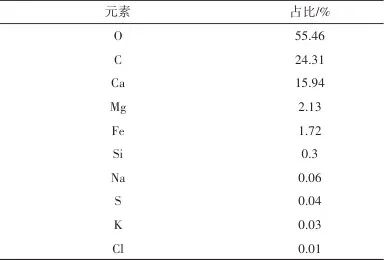

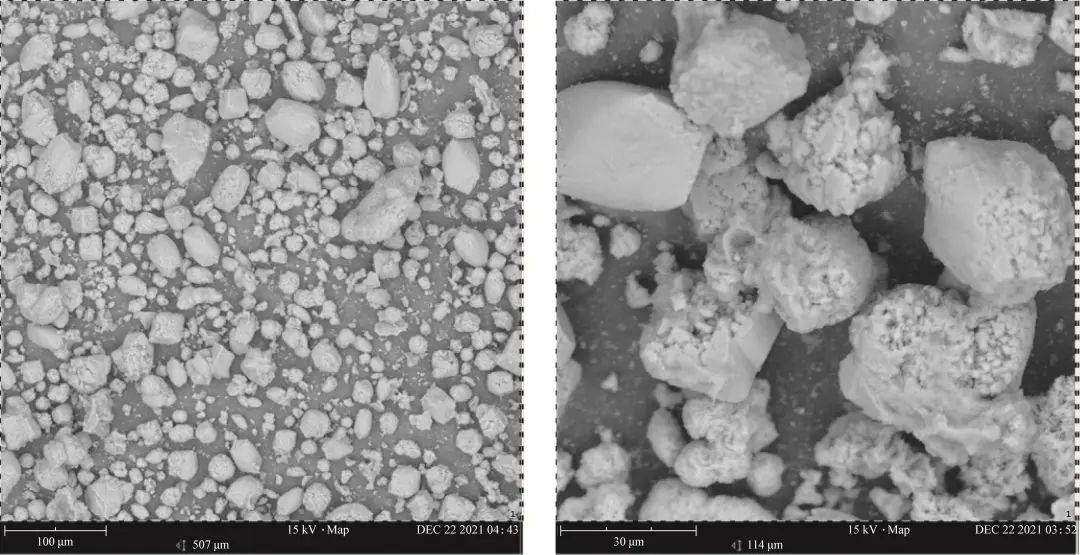

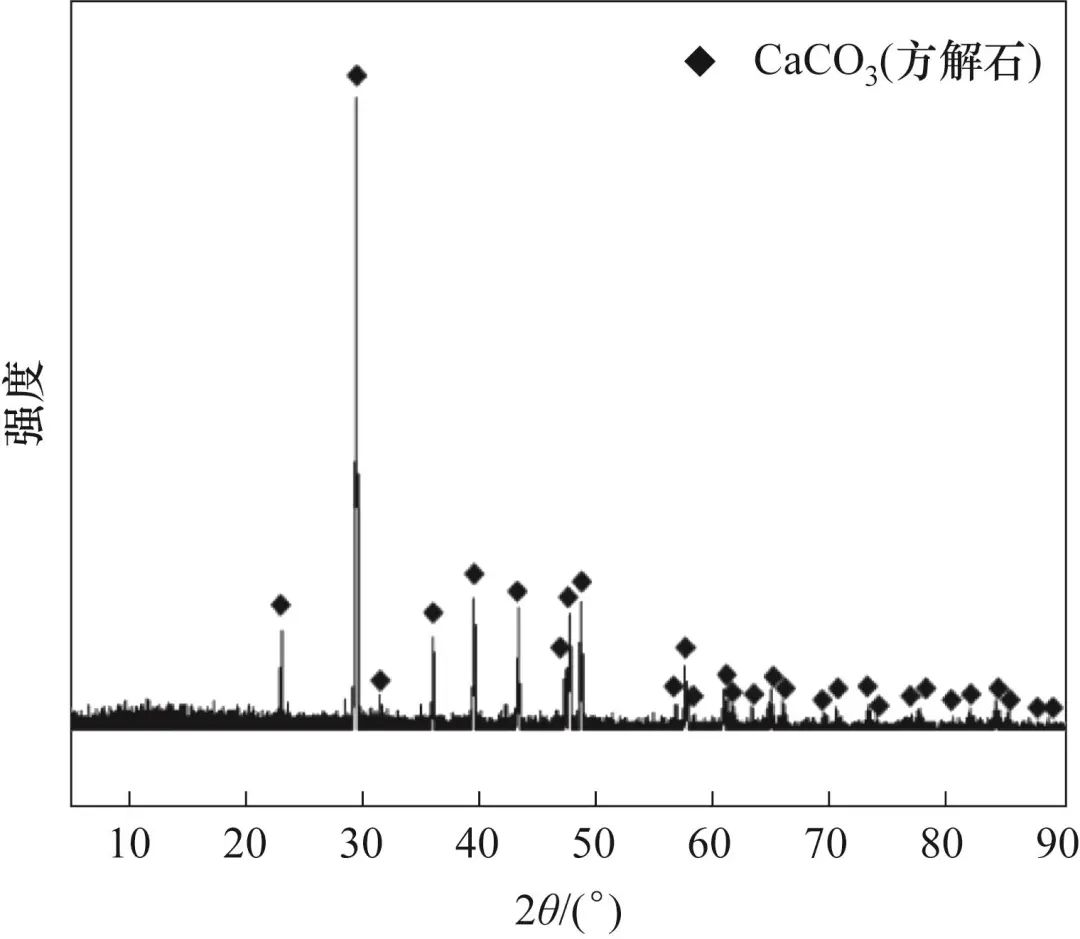

1.1 結(jié)晶體成分分析

表1 結(jié)晶體樣品元素種類Table 1 Crystal sample element species

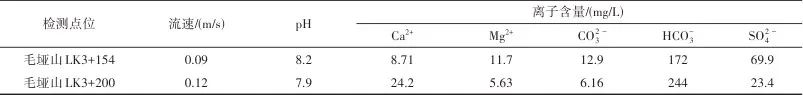

1.2 水樣分析

的平均濃度高達(dá)208 mg/L,這為結(jié)晶離子的接觸提供了條件。

的平均濃度高達(dá)208 mg/L,這為結(jié)晶離子的接觸提供了條件。表2 毛埡山隧道排水管水樣分析Table 2 Maoyashan tunnel drainage pipe water sample analysis

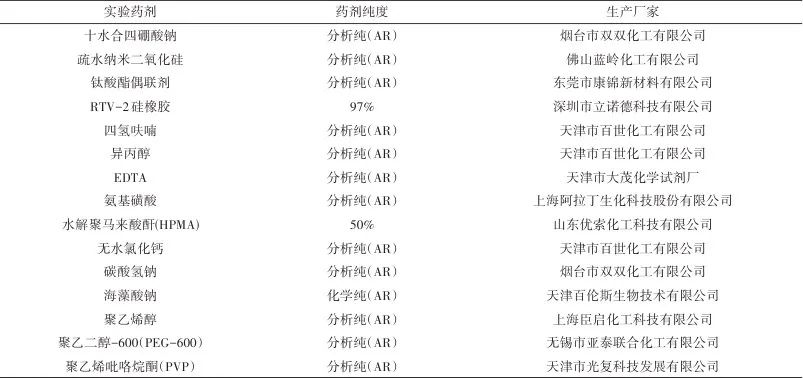

2 實(shí)驗(yàn)儀器和實(shí)驗(yàn)藥劑

表3 實(shí)驗(yàn)藥劑Table 3 Experimental reagents

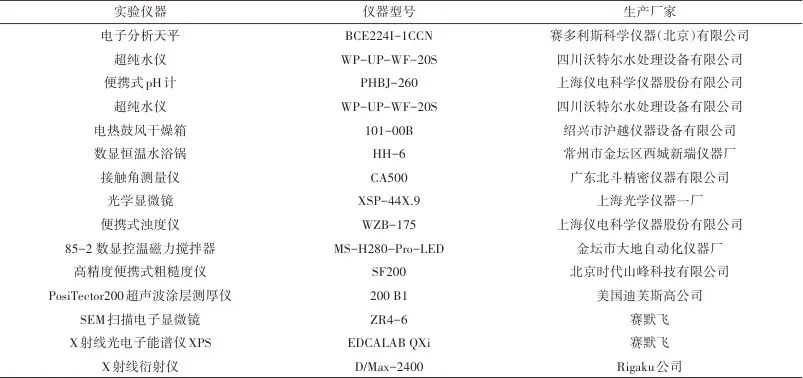

表4 實(shí)驗(yàn)儀器Table 4 Experimental instruments

3 實(shí)驗(yàn)方法

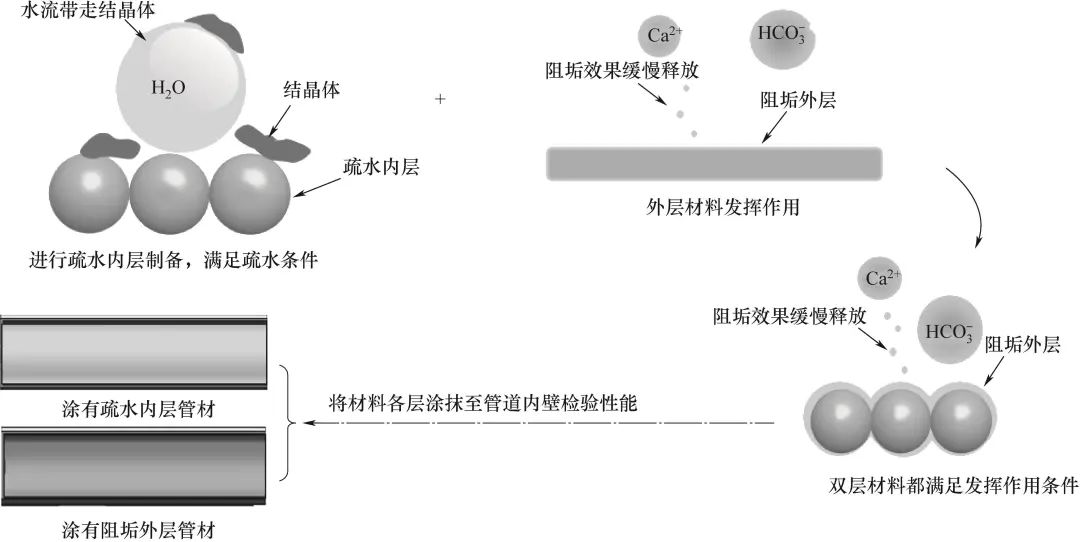

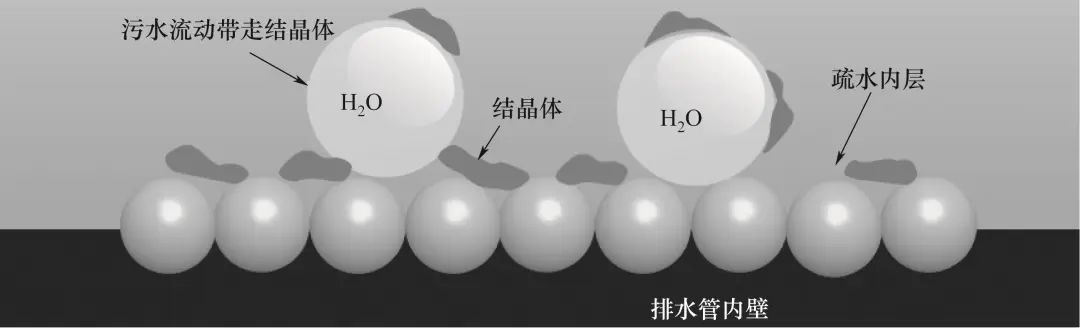

3.1 研發(fā)思路

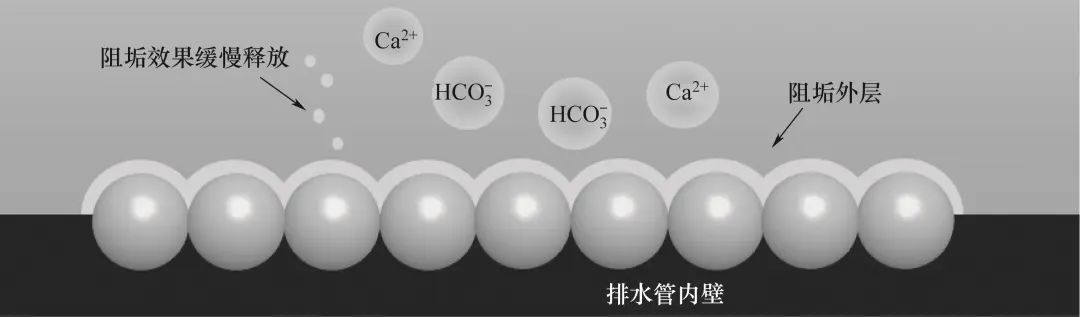

發(fā)生反應(yīng)生成的。通過(guò)選擇適宜的阻垢劑,與具有緩釋性能的膠材料進(jìn)行充分混合,與水中的Ca2+和

發(fā)生反應(yīng)生成的。通過(guò)選擇適宜的阻垢劑,與具有緩釋性能的膠材料進(jìn)行充分混合,與水中的Ca2+和 反應(yīng),以達(dá)到緩慢且長(zhǎng)期釋放藥劑、減少結(jié)晶體生成的作用(圖6)。

反應(yīng),以達(dá)到緩慢且長(zhǎng)期釋放藥劑、減少結(jié)晶體生成的作用(圖6)。

3.2 實(shí)驗(yàn)方法

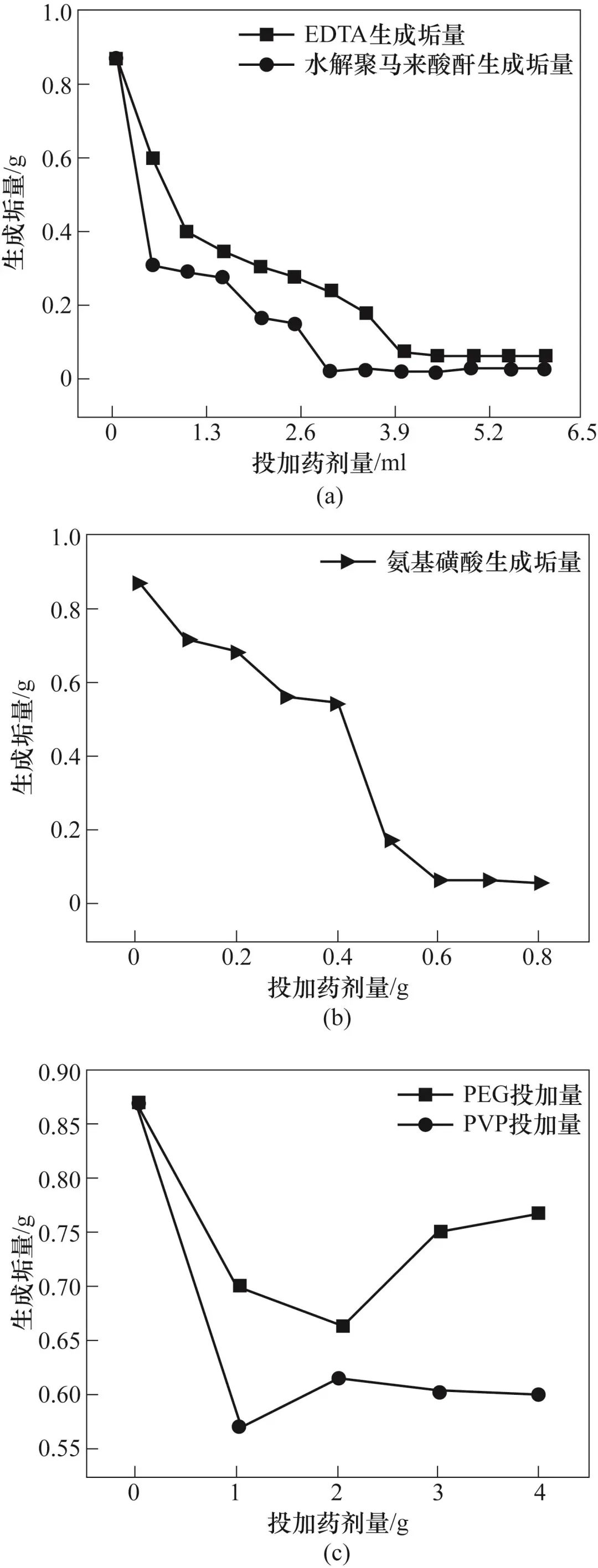

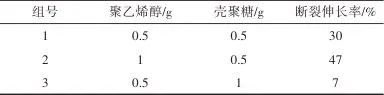

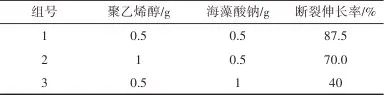

發(fā)生反應(yīng),從而阻止這兩種離子結(jié)合,防止方解石型碳酸鈣結(jié)晶體的生成。選擇EDTA、氨基磺酸、水解聚馬來(lái)酸酐、PVP和PEG作為備選阻垢劑,這些藥劑的選擇依據(jù)其特性和效果進(jìn)行,如EDTA、PVP和PEG能與鈣離子絡(luò)合,防止結(jié)晶體生成,氨基磺酸能夠預(yù)防且去除垢類物質(zhì),對(duì)生態(tài)具有安全性,水解聚馬來(lái)酸酐不僅穩(wěn)定且阻垢;選擇聚乙烯醇、海藻酸鈉和殼聚糖作為膠材料的備選藥劑,聚乙烯醇因其優(yōu)異的黏合性和水溶性而受到青睞,而海藻酸鈉和殼聚糖則是天然來(lái)源的環(huán)保材料。此外,它們均具有良好的強(qiáng)度和耐水性,在膠材料領(lǐng)域被廣泛應(yīng)用。將阻垢溶劑與膠材料混合,保護(hù)疏水內(nèi)層的同時(shí)發(fā)揮阻垢作用,提高材料的功能性。

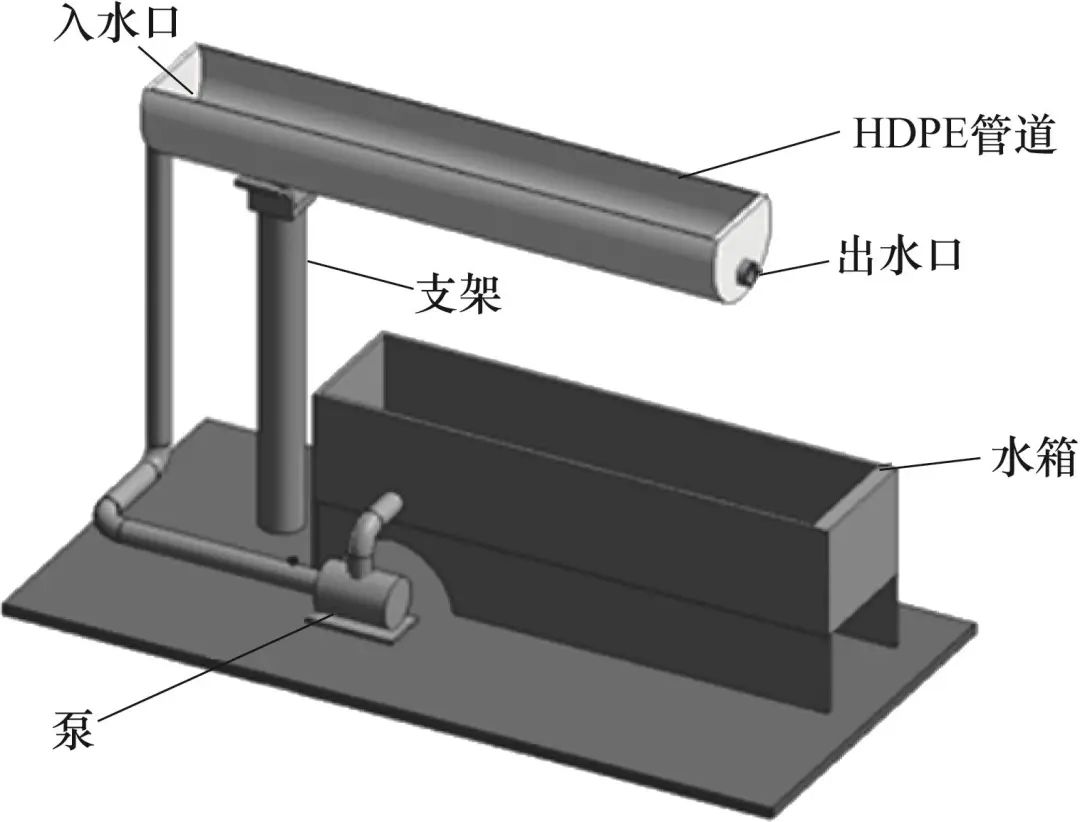

發(fā)生反應(yīng),從而阻止這兩種離子結(jié)合,防止方解石型碳酸鈣結(jié)晶體的生成。選擇EDTA、氨基磺酸、水解聚馬來(lái)酸酐、PVP和PEG作為備選阻垢劑,這些藥劑的選擇依據(jù)其特性和效果進(jìn)行,如EDTA、PVP和PEG能與鈣離子絡(luò)合,防止結(jié)晶體生成,氨基磺酸能夠預(yù)防且去除垢類物質(zhì),對(duì)生態(tài)具有安全性,水解聚馬來(lái)酸酐不僅穩(wěn)定且阻垢;選擇聚乙烯醇、海藻酸鈉和殼聚糖作為膠材料的備選藥劑,聚乙烯醇因其優(yōu)異的黏合性和水溶性而受到青睞,而海藻酸鈉和殼聚糖則是天然來(lái)源的環(huán)保材料。此外,它們均具有良好的強(qiáng)度和耐水性,在膠材料領(lǐng)域被廣泛應(yīng)用。將阻垢溶劑與膠材料混合,保護(hù)疏水內(nèi)層的同時(shí)發(fā)揮阻垢作用,提高材料的功能性。 | (1) |

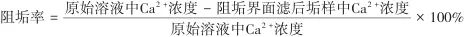

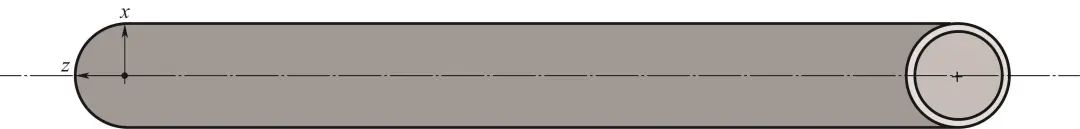

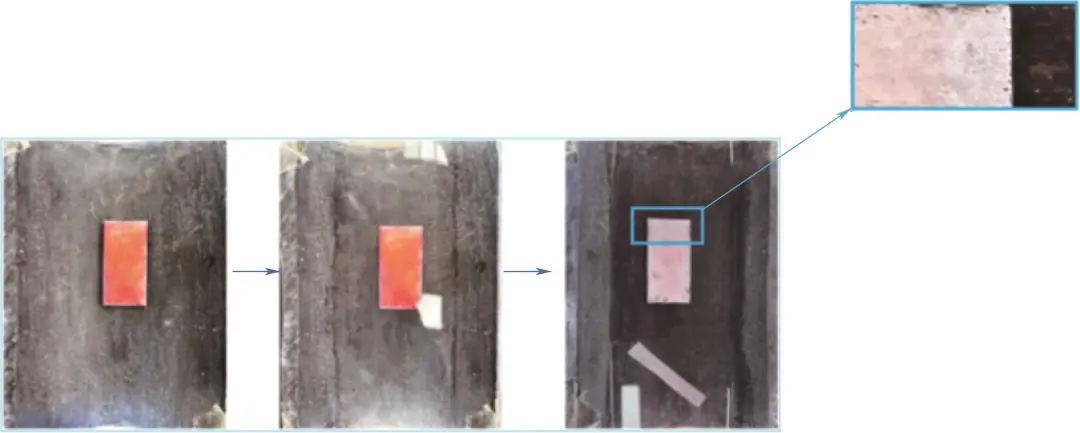

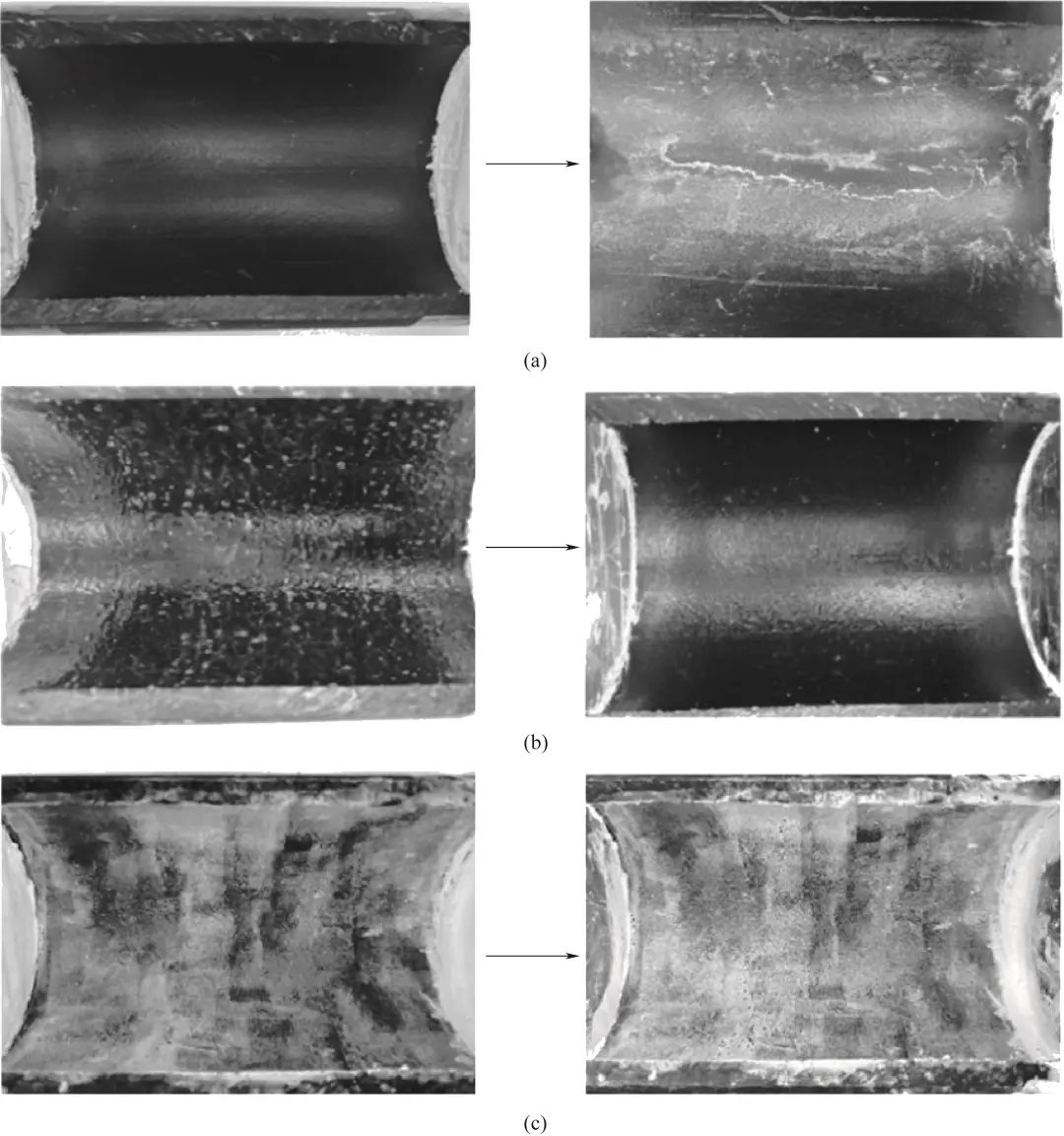

3.3 模擬實(shí)驗(yàn)

| (2) |

| (3) |

| (4) |

| (5) |

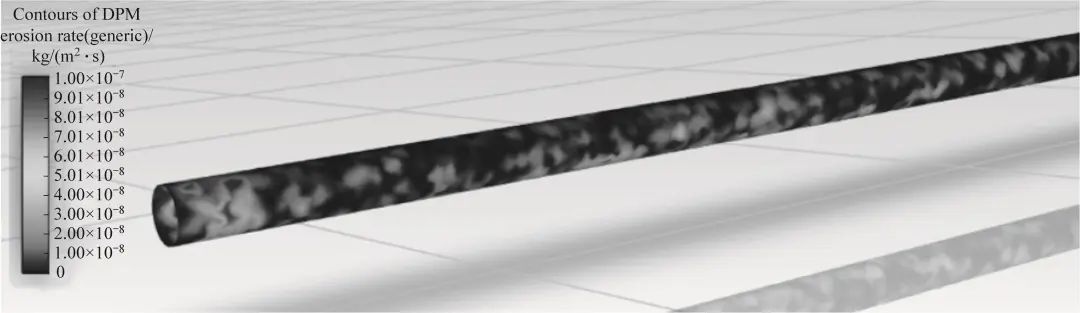

為疏水涂層厚度,m;ρ為涂層的密度(疏水內(nèi)層密度為1.07836 kg/cm3,阻垢外層密度為1.47322 kg/cm3),kg/m3;δ為磨損率,kg/(m2·s)。通過(guò)比較理論耐久時(shí)長(zhǎng)與模擬耐久時(shí)長(zhǎng),判斷模型的預(yù)測(cè)誤差[式(6)]。一般而言,計(jì)算和仿真的誤差最大不超過(guò)20%,最佳誤差一般控制在5%以下。

為疏水涂層厚度,m;ρ為涂層的密度(疏水內(nèi)層密度為1.07836 kg/cm3,阻垢外層密度為1.47322 kg/cm3),kg/m3;δ為磨損率,kg/(m2·s)。通過(guò)比較理論耐久時(shí)長(zhǎng)與模擬耐久時(shí)長(zhǎng),判斷模型的預(yù)測(cè)誤差[式(6)]。一般而言,計(jì)算和仿真的誤差最大不超過(guò)20%,最佳誤差一般控制在5%以下。 | (6) |

4 結(jié)果與討論

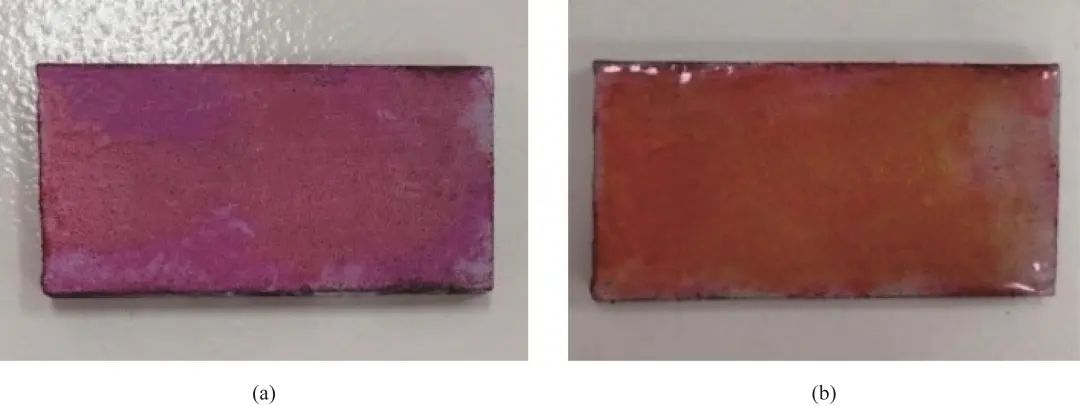

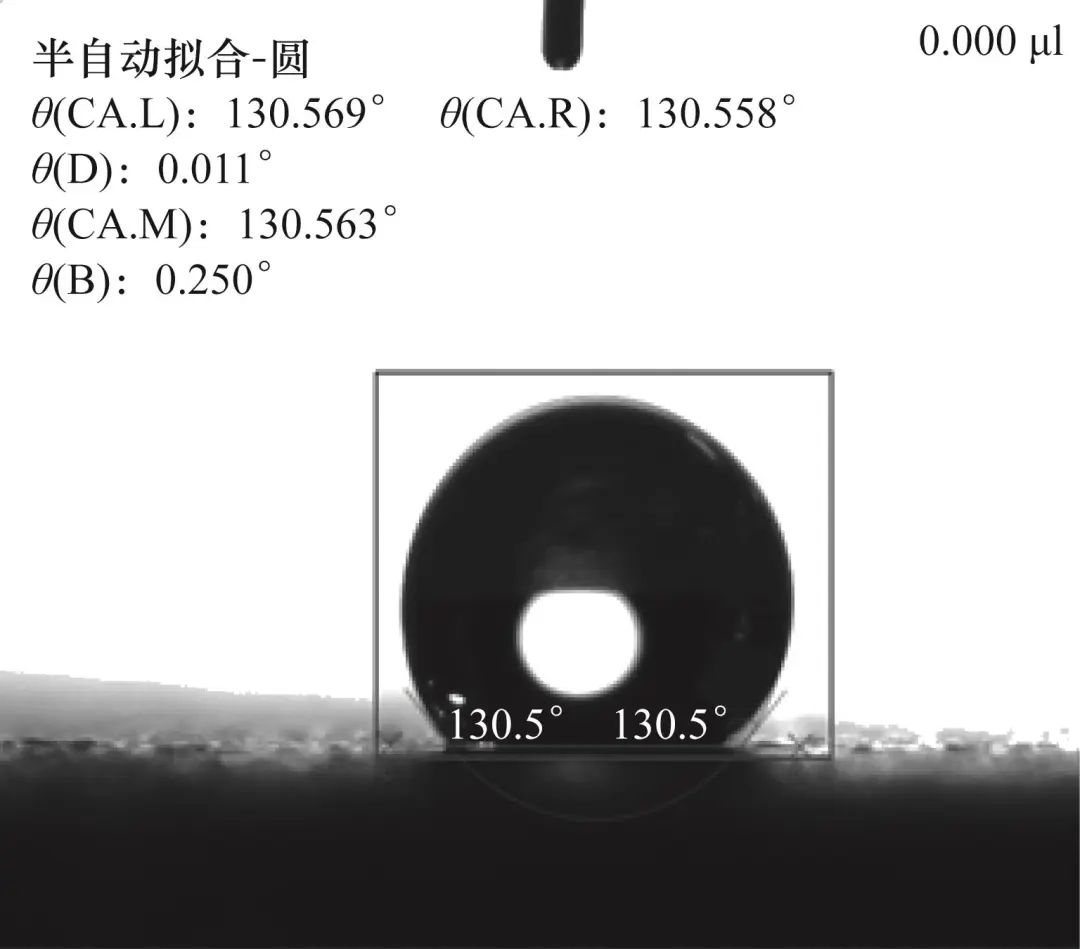

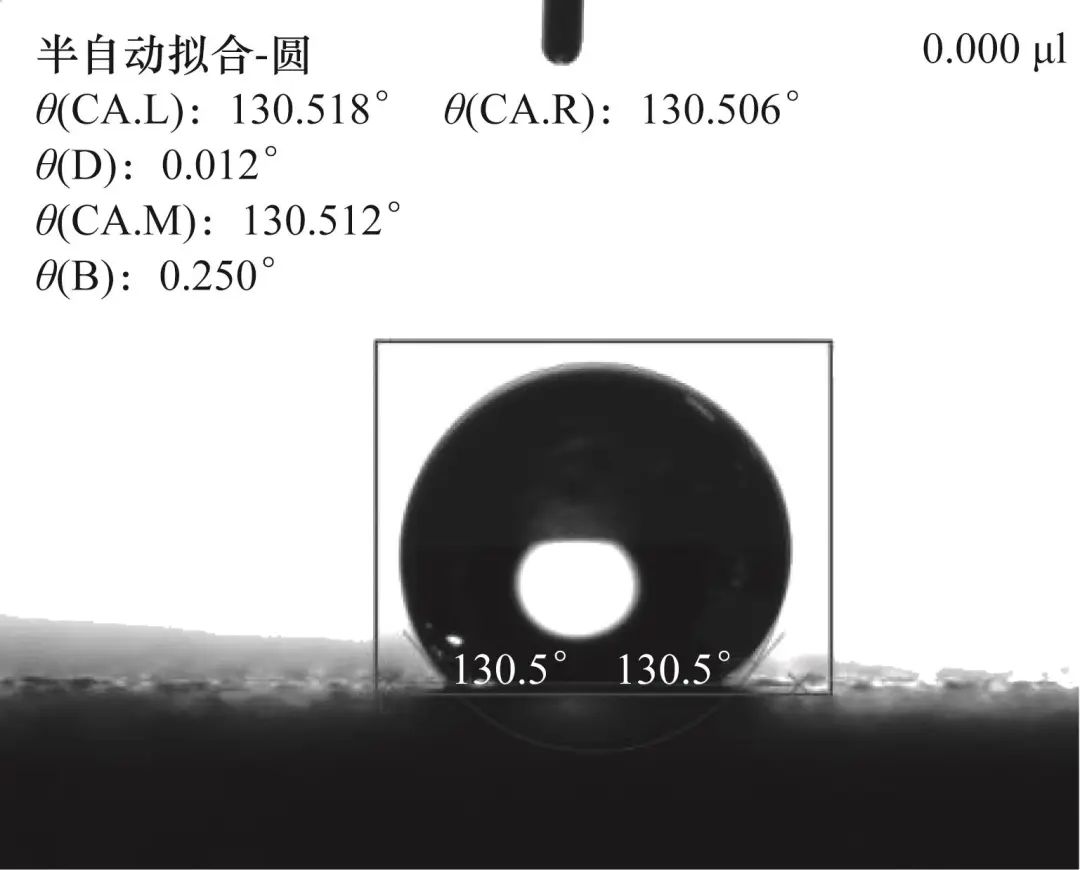

4.1 疏水內(nèi)層制備實(shí)驗(yàn)和結(jié)果

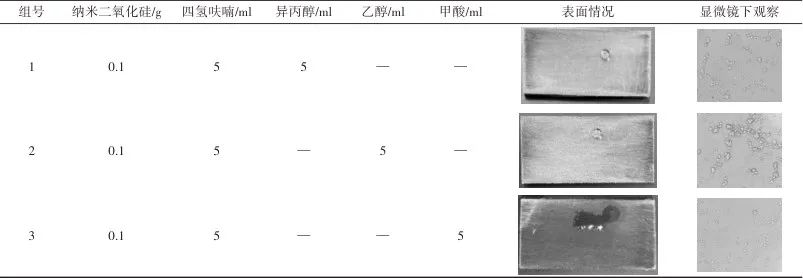

表5 溶劑揮發(fā)劑篩選Table 5 Solvent volatile screening

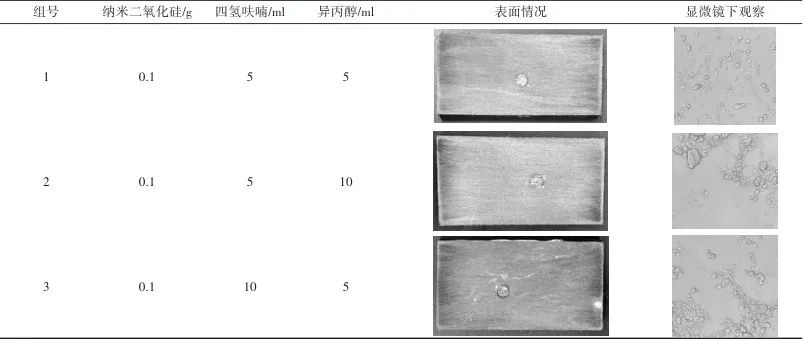

表6 篩選稀釋劑與溶劑揮發(fā)劑配比(一)Table 6 Screening diluent and solvent volatile ratio(Ⅰ)

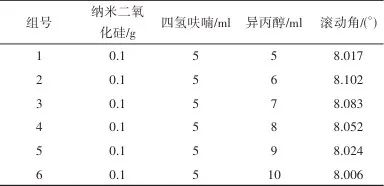

表7 篩選稀釋劑與溶劑揮發(fā)劑配比(二)Table 7 Screening diluent and solvent volatile ratio(Ⅱ)

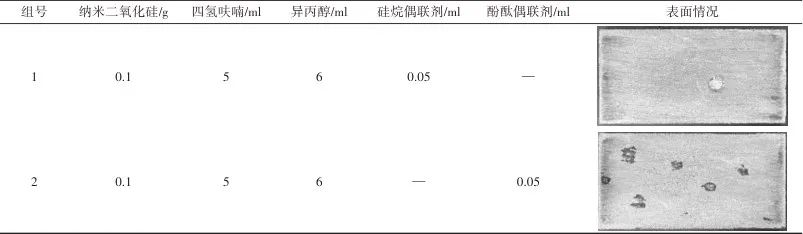

表8 篩選界面活性劑Table 8 Screening interface active agent

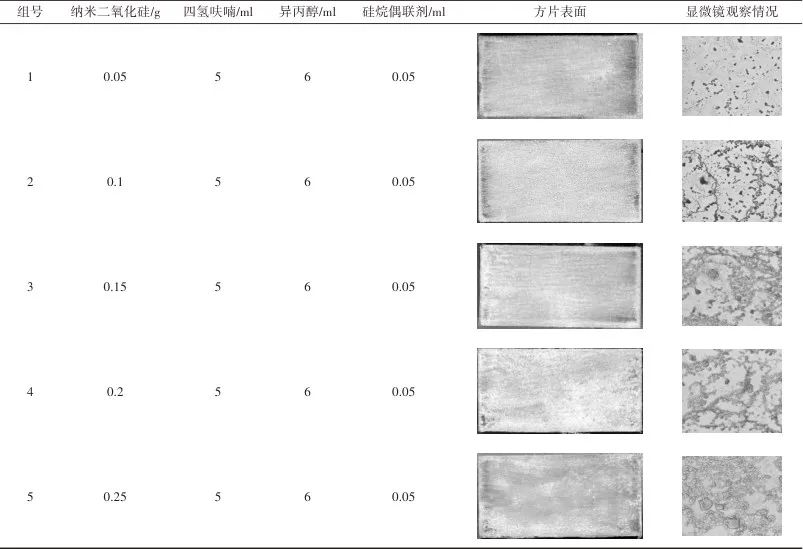

表9 確定最佳納米填充劑用量Table 9 Determine the optimal nano filler dosage

4.2 阻垢外層制備實(shí)驗(yàn)和結(jié)果

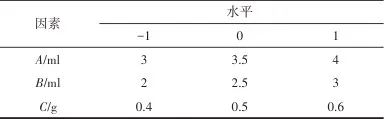

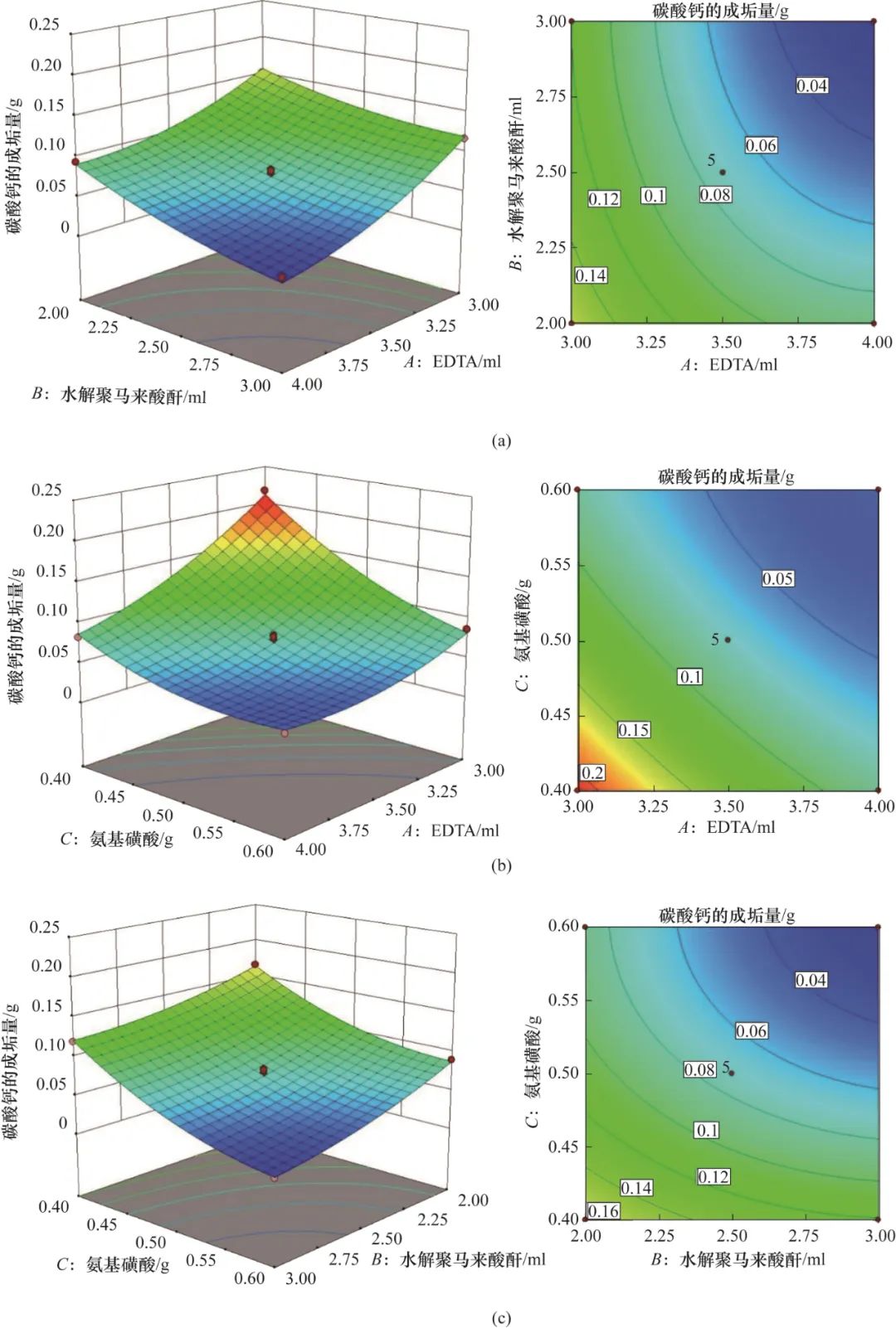

表10 三因素水平響應(yīng)曲面分析實(shí)驗(yàn)設(shè)計(jì)Table 10 Three factor horizontal response surface analysis experimental design

表11 響應(yīng)曲面優(yōu)化碳酸鈣的結(jié)晶量實(shí)驗(yàn)設(shè)計(jì)與結(jié)果Table 11 Experimental design and results of response surface optimization for calcium carbonate crystallization

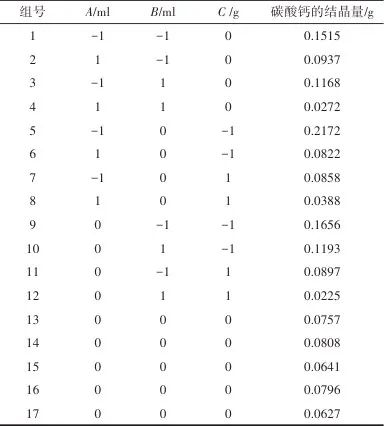

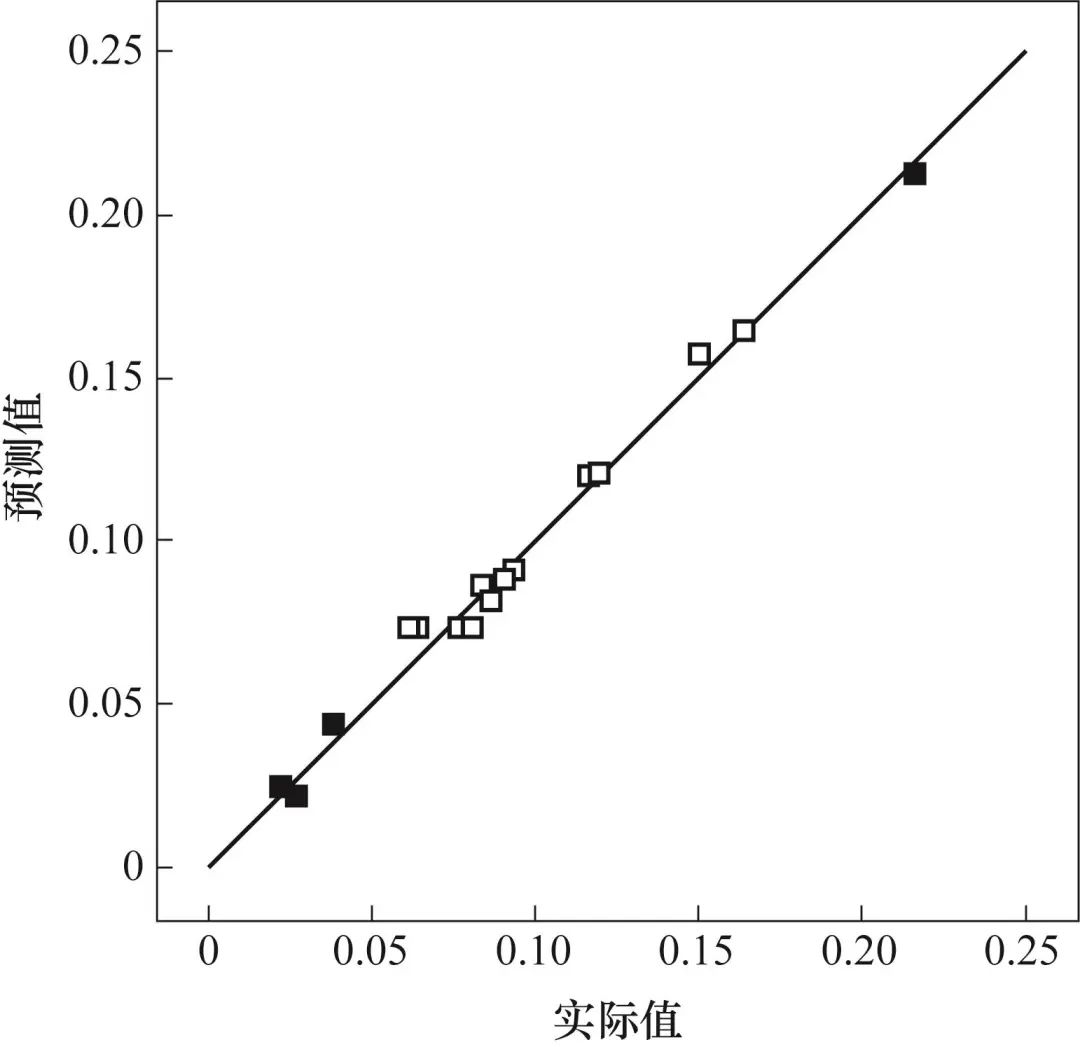

| (7) |

表12 碳酸鈣的結(jié)晶量模型及回歸系數(shù)的回歸分析結(jié)果Table 12 The results of regression analysis of calcium carbonate crystal volume model and regression coefficient

注:P < 0.0001為極顯著,用**表示,P < 0.05為顯著,用*表示,P > 0.05為不顯著,用ns表示;F 值的大小是評(píng)價(jià)各變量對(duì)響應(yīng)值影響程度的重要指標(biāo),F 值越大,表明有關(guān)模型分量對(duì)響應(yīng)影響貢獻(xiàn)度越高。

表13 聚乙烯醇與殼聚糖混合膠材料Table 13 Mixed rubber materials of polyvinyl alcohol and chitosan

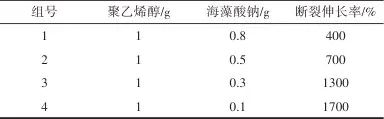

表14 聚乙烯醇和海藻酸鈉混合膠材料(一)Table 14 Polyvinyl alcohol and sodium alginate mixed rubber material(Ⅰ)

表15 聚乙烯醇和海藻酸鈉混合膠材料(二)Table 15 Polyvinyl alcohol and chitosan mixed rubber material(Ⅱ)

4.3 模擬實(shí)驗(yàn)結(jié)果

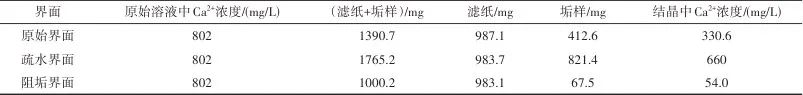

表16 實(shí)驗(yàn)室模擬結(jié)晶情況Table 16 Laboratory simulation of crystallization

表17 涂覆有疏水內(nèi)層的管壁粗糙度測(cè)量(30 d)Table 17 Wall roughness measurement with a hydrophobic inner coating (30 d)

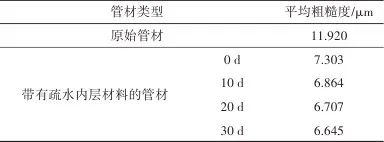

表18 涂覆有阻垢外層的管壁粗糙度測(cè)量(30 d)Table 18 Wall roughness measurement with a hydrophobic inner coating (30 d)

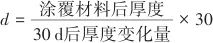

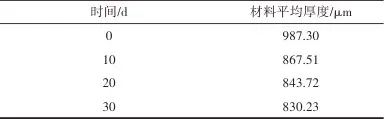

表19 涂覆有疏水內(nèi)層的管壁厚度測(cè)量(30 d)Table 19 Wall thickness measurement with a hydrophobic inner coating (30 d)

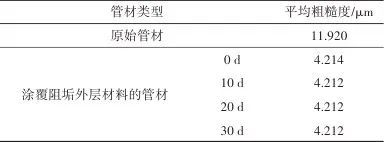

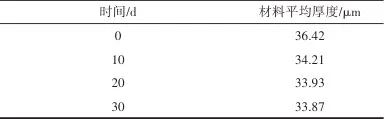

表20 涂覆有阻垢外層的管壁厚度測(cè)量(30 d)Table 20 Wall thickness measurement with scale resistant coating (30 d)

。

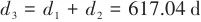

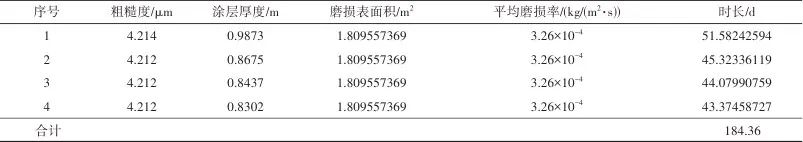

。表21 Ansys fluent軟件模擬疏水內(nèi)層耐久時(shí)長(zhǎng)Table 21 Ansys fluent software simulates the duration of coating

表22 Ansys fluent軟件模擬阻垢外層耐久時(shí)長(zhǎng)Table 22 Ansys fluent software simulates the duration of coating

d。

d。5 結(jié) 論

Utility model relates to double - layer anti - scale and hydrophobic coating that inhibits crystal formation in tunnel drainage pipe

HU Jiawei  WANG CongLIU Meijing

WANG CongLIU Meijing

(School of Civil Engineering, Lanzhou University of Technology, Lanzhou 730050, Gansu, China)

通訊作者及第一作者:胡家瑋(1982—),男,博士,副教授,hujiawei@lut.edu.cn